I first met Geo when my wife and I lived up in Evanston, IL. He was iconic on our street, his long gray hair always a sight to see. He and his family own several of my artworks, and I have always enjoyed my conversations with the man. He is a gentleman and a scholar, and given to grand gestures and deep sincerity. Once, back in 2009, he drove 8 hours (one way!) to see an exhibition of mine and take me out to dinner. He’s a really unique soul and I’m glad to know him.

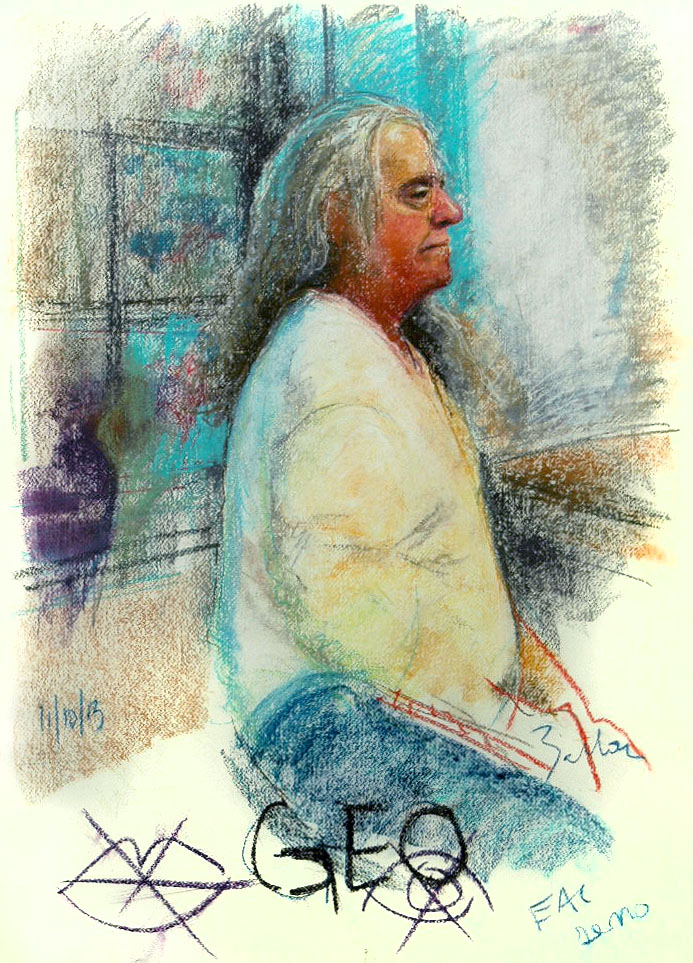

In late 2013 I had the opportunity to draw Geo at a pastel workshop I was giving at the Evanston Art Center (in conjunction with an exhibition I was in there). I was glad that Geo was willing to sit for me; I’d always though him a man possessing a regal bearing, similar to a Founding Father or deity.

Geo the Woodworker, Pastel on toned paper, 24 by 18 inches. 2013.

Geo the Woodworker, Pastel on toned paper, 24 by 18 inches. 2013.

After I began working on my Becoming the Student series, I realized that my drawing of Geo was, perhaps, the true initiation of the project. So, in the spirit of Becoming the Student, I asked Geo to tackle a few questions for me, and his answers are below. After reading through them, be sure to check out his website to see his fantastic work!

On How Long He Has Been a Woodworker

“I started in with wood even before I knew it. Then in college I had the opportunity to study with a real master carver and through that experience I just knew… it seemed to be in my blood. That was back in 1975, so at least that long.”

On What Life Lessons and/or Epiphanies Working With Wood Has Given Him

“I guess I’ve learned that it – the work, regardless of subject or use – is all the same. Here’s the bottom line: it is not what you do but HOW YOU DO IT. Every stroke of the chisel counts, whether you are carving The Baby Jesus, the Presidential Shield, or just making a Push Stick to use on that big table saw. You must come to know that everything counts forever or nothing matters at all. I would suggest that you move toward the light in all things.”

On The Most Beautiful Work of Art He Has Seen or Heard

“First, a poem: Maud Muller, by John Greenleaf Whittier. Second: my Foo Dogs. My wife gave them to me for my 50th birthday and they are as good as good gets!”

On How His Creativity Had Changed Over The Years

“I believe it has gotten thicker, not just longer or with greater elasticity. This is a blessing to be sure. But all things considered I’d have to say it’s thicker, yeah. More thick.”

On What Values Motivate Him as a Man, Dad, and Artist

“OTHERS! All my life, it has been the ability I have to help others, to inspire others, to challenge them. That’s what I love.”

On How To Recharge Creativity

“Go outside. OPEN your eyes. Read a book. Take in a beach, a mountain, a river. Go to the Wailing Wall. SEE and BE. Remember: hard work is hard work. The ‘best you can do’ is rarely the easiest answer.”

On His Earliest Art Experience

“I’m not sure how old I was, but I have clear early memories of my aunt sitting in a kitchen somewhere knitting. I asked what she was making and she said, “Another sweater, just like the one your uncle is wearing.” Well that seemed hard to believe: ‘YOU made THAT??’ Sure enough. At the time I didn’t know yet that my mom and her sisters could knit like that: an Irish fisherman’s sweater with those rope patterns up the front. How could a person do that? It was impossible for me to imagine how it was done. It’s like at the Consecration, but even better. I mean, you get to WEAR the sweater. Yes, I was raised Catholic; I always thought that catholic meant, ‘closer to the real Art’.”

On How Being a Dad Has Changed His Work

“My son is here to remind me that we are all but links in an endless chain. As the old poem (Thanatopsis, by William Cullen Bryant) goes:

‘The youth in life’s green spring, and he who goes

In the full strength of years, matron and maid,

The speechless babe, and the gray-headed man

Shall one by one be gathered to thy side

By those who in their turn shall follow them.’

Read more at http://www.poetry-archive.com/b/thanatopsis.html#I2Z2Tok0sel6VB3M.99

SO LIVE!”

~

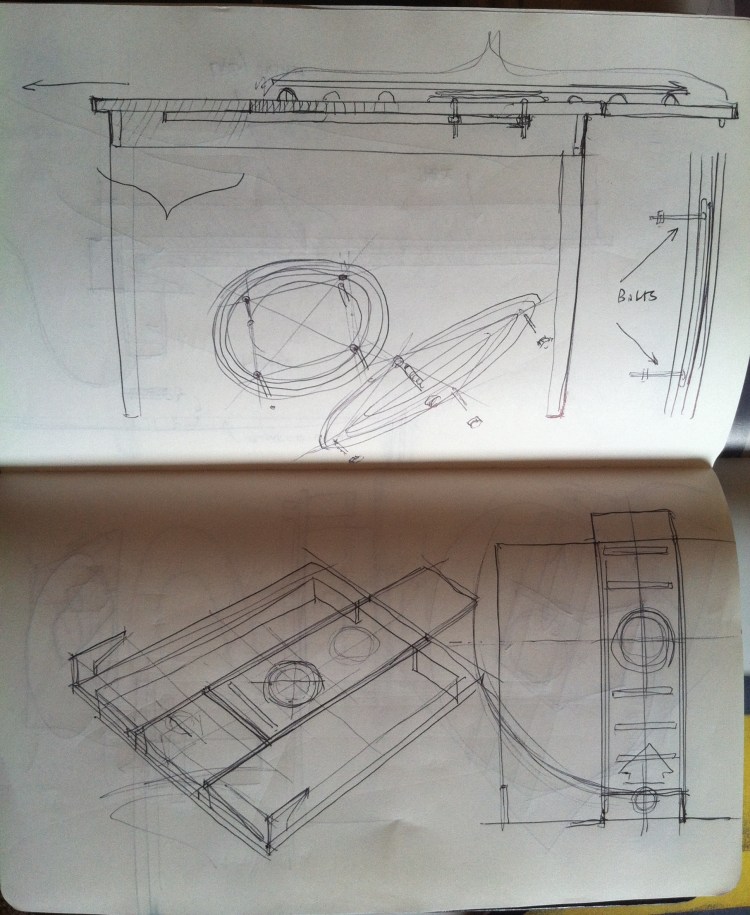

Geo’s self portrait before the portrait demo I made. Epic!

Geo’s self portrait before the portrait demo I made. Epic!

~

Thanks, Geo, for your friendship and exuberance over the years!